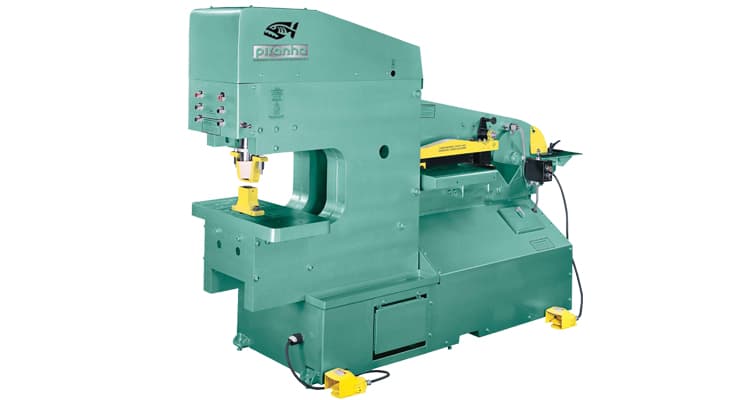

Piranha hydraulic ironworker machines provide you with top-tier quality, innovative features, and unparalleled durability for all metal manufacturing needs. Our ironworker machines can range from 50 to 140 tons and include single-operator and dual-operator models. Every Piranha ironworker machine includes reliability, machine set-up time savings, versatility through a wide range of tooling and attachments, and superior factory engineering and support.

Piranha ironworker machines give metal fabricators outstanding quality, innovative features, and range from 50 to 140 tons. Every Piranha ironworker provides quality work, savings in machine set-up time, versatility through a wide range of tooling, and superior factory engineering and support. Piranha Single Operator Ironworker machines are capable of performing most applications. However, when two simultaneous operations are required (e.g. punching and notching), a dual operator ironworker machine fits the bill.